Leveraging on sophisticated infrastructure, we manufacture and supply a wide range of axial flow fans. Fabricated using quality raw material, these axial flow fans are suitable for large volume of air at high pressures. To cater to the needs of different industries, our range of axial flow fans are available in various specifications. Easily installed, these fans are known for their high performance and low power consumption. Further, we can also customized these axial flow fans as per the specifications laid down by our clients.

The major types of axial flow fans are: tube axial, vane axial and propeller.

| Types of Axial Fans |

| Tube Axial |

Vane Axial |

Propeller |

|

|

|

|

|

|

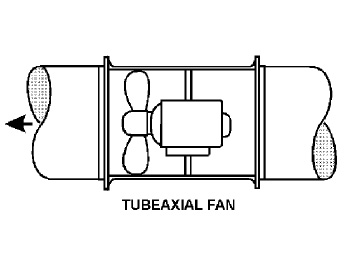

Tubeaxial fans have a wheel inside a cylindrical housing, with close clearance between

blade and housing to improve airflow efficiency. The wheel turn faster than propeller fans,

enabling operation under high-pressures 250 – 400 mm WC. The efficiency is up to 65%.

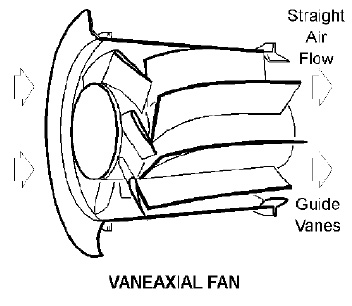

Vaneaxial fans are similar to tubeaxials, but with addition of guide vanes that improve efficiency

by directing and straightening the flow. As a result, they have a higher static pressure

with less dependence on the duct static pressure. Such fans are used generally for pressures upto

500 mmWC. Vaneaxials are typically the most energy-efficient fans available and should be

used whenever possible.

Propeller fans usually run at low speeds and moderate temperatures. They experience a

large change in airflow with small changes in static pressure. They handle large volumes of air

at low pressure or free delivery. Propeller fans are often used indoors as exhaust fans. Outdoor

applications include air-cooled condensers and cooling towers. Efficiency is low – approximately

50% or less. |